In industrial processes, the efficient handling and distribution of fluids within vessels and tanks is paramount.

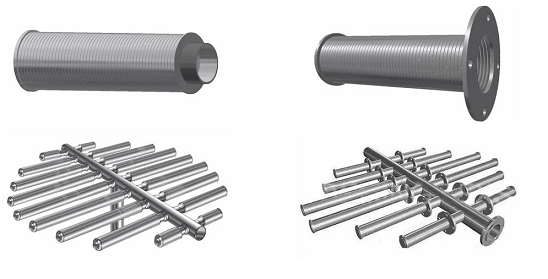

Hub and header laterals, also known as wedge wire lateral assemblies, are essential components in vessels and tanks used for the distribution and collection of fluids.

Whether in the chemical, petrochemical, water treatment, or other industries, the design and functionality of the hub and header lateral play a crucial role in ensuring optimal performance.

We can design wedge wire screen hub and header laterals based on Vessel/Filter size, flange size, flow rate, and medium sizes.

Contact us

E-mail: sales@yubofilter.com

WhatsApp: 86 13653285589

Understanding Hub and Header Lateral Used for Vessel or Tank

The hub systems consist of a central hub or manifold connected to multiple lateral pipes that radiate outward, similar to the spokes of a wheel. The primary purpose of a hub system is to evenly distribute or collect fluids across the vessel or tank.

Hub systems come in various designs to accommodate different applications. Common variations include radial hub systems, circular hub systems, and even custom-designed hubs based on specific process requirements.

Header lateral systems are another integral part of fluid management within vessels and tanks. These systems consist of headers (main pipes) connected to lateral pipes with precision-drilled holes or slots. The lateral pipes, in turn, facilitate the even distribution or collection of fluids.

Header lateral systems are engineered with precision to control the flow rates and distribution of fluids. Designing the drilled holes or slots in the lateral pipes is crucial for achieving uniform flow and preventing issues such as channeling.

Header lateral systems can be customized with support grids and filter nozzles in media retention or filtration. This allows for the effective separation of solids from liquids, ensuring the purity of the final product.

1. Water Treatment

In water treatment plants, both hub and header lateral systems are employed for processes such as filtration, ion exchange, and backwashing. The precise distribution of water in these systems ensures efficient treatment and high-quality output.

2. Chemical and Petrochemical Industries

In chemical and petrochemical processes, where a variety of corrosive fluids are handled, these systems play a vital role in maintaining the integrity of vessels and tanks. They enable controlled mixing, separation, and efficient transfer of fluids.

In conclusion, the efficiency of vessels and tanks in industrial processes is heavily reliant on the careful integration of components like hub and header lateral systems. Their role in the even distribution and collection of fluids is crucial for the success of various applications, ranging from water treatment to chemical processing.